to minimize paper waste

Who is

lineapack

Forty years of experience gained thanks to constant investments in the research and development of environmentally friendly products and cutting-edge production systems. Firmly present on the Italian territory, we are increasingly addressing foreign markets. Our dynamic and determined management team continues the path traced by founder Bruno Chinello, in the wake of a corporate identity which has deep local roots, but above all an international business vision and a strong customer orientation.

The origins

In the seventies Bruno Chinello handcrafted, with the collaboration of his wife Emilia, bags for bread, flour and coffee, as well as paper for sugar sachets. It was only the beginning of the lengthy Lineapack Srl history, a family business which, over time, has made the productive link between industrious creativity and innovative drive indissoluble. A bond that was strengthened with the entry of his sons Damiano, Tiziano, Michele and Pierluigi, while the company gradually grew with the evolution of market needs. Since that distant 1974, it has helped to “bag” an infinite number of products: first thanks to special large and small sachets for opticians, hospitals, banks and insurance companies; later, as the demand for archive packaging disappeared due to the spread of IT, with a return to its origins, that is to the production of sachets, bags, paper rolls and films for the food sector. Over the years, it has established itself in the food packaging sector (link to food packaging section) and also in non-food packaging (link to others packaging section), offering low environmental impact solutions, many of which are patented. They stem from a passion for research and innovative commitment: a passion that has always involved everyone who works in the company, from salespeople to technicians and production workers.

Quality,

innovation,

environment.

These are the values we believe in: a quality that pervades the company at every level, embraces respect for the environment and becomes tangible in recyclable packaging, with highly performing, personalised and certified requirements. Mono-film bags and packaging and multilayer laminates, both in reels and in bags, which combine eco-sustainable raw materials with constant, inexhaustible technological research. All in order to effectively and punctually satisfy customer requests, even the most complex ones.

Eco-sustainable

quality.

Lineapack is synonymous with excellence starting from the raw materials, which we test and select in compliance with precise technical, application and above all environmental standards. We only use controlled materials, with “green” requirements:

- all papers are PEFC and FSC certified, i.e. generated from cellulose from responsible forests, with guaranteed traceability and eco-sustainability

- the glues are almost exclusively water-based, i.e. solvent-free, therefore compatible with separate waste collection and composting

- the inks for printing on paper and film are all water-based, with certifications, as a guarantee of total reliability and safety. Selected from leading Italian suppliers based on high definition printing parameters, scratch resistance and chromatic vividness, they are the result of joint research with ink formulators to guarantee the same yield as solvent-based inks, but with total eco-friendly respect.

The entire production management is based on social and environmental responsibility. Suffice it to say that 80% of our energy needs is covered by “clean” energy, produced thanks to a high-performance photovoltaic system, installed on the roof of our factory, which helps to reduce CO2 emissions into the atmosphere, in favour of a healthier and more liveable environment.

Certificazioni

ISO 9001:2008

PEFC o FSC

Qualità

ecosostenibile.

- tutte le carte sono certificate PEFC e FSC, ovvero generate da cellulosa proveniente da foreste responsabili, garantite nella tracciabilità ed ecosostenibilità

- le colle sono quasi esclusivamente a base d’ acqua, ovvero prive di solventi, quindi compatibili con la raccolta differenziata e il compostaggio

- gli inchiostri per la stampa su carta e film sono tutti a base d’acqua, dotati di certificazioni, a garanzia di assoluta affidabilità e sicurezza. Selezionati presso fornitori leader italiani in base a parametri di elevata definizione di stampa, resistenza al graffio e vividezza cromatica, sono il risultato di una ricerca congiunta con i formulatori di inchiostri per garantire la medesima resa degli inchiostri a solvente, ma totale rispetto ecologico.

SWe print and laminate exclusively

with Acquapack®

water-based colours and glues

Patents

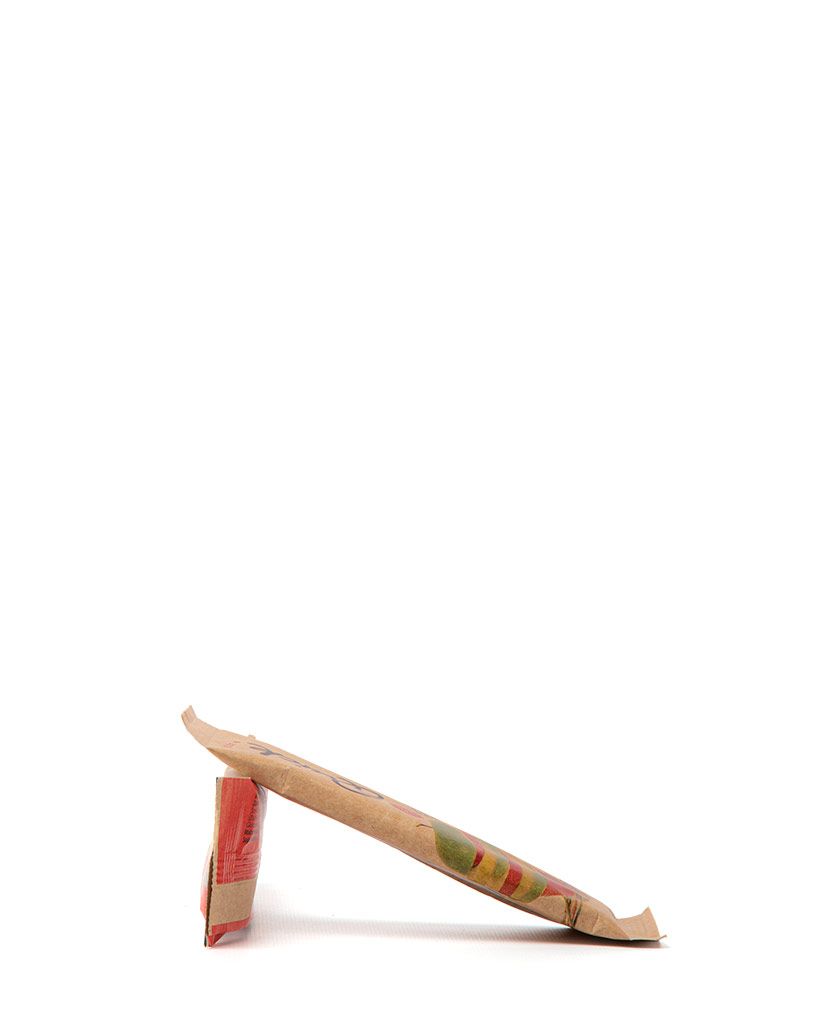

Our solutions represent small “revolutions” in the way we design and produce our packaging, respecting the environment in which we live. For this reason, many of them are patented: first of all, Sbucciapack, whose patent was filed in 2012, the first and only paper-plastic film laminating system, which allows the two elements to be separated easily, quickly and cleanly, with the advantage of being able to dispose of them separately, without generating non-recyclable waste. Sbucciapack also reduces the amount of film used in packaging: the paper lamination compensates and improves the consistency and sturdiness of the packaging. We have achieved important results, but we never stop improving. For us, research has no limits and remains a constant in the field of materials, processes and technologies used: an activity to be carried out in the name of environmental sustainability.

The

Made in Italy guarantee.

The pursuit of excellence in every production aspect translates into real added value for our bags and flexible packaging. In-home technicians and production workers collaborate closely, sharing know-how and passion, to guarantee products with great attention to the smallest details, in the name of the best Italian tradition. The use of machinery built ad hoc and customised in terms of production functions, according to assessments born from our experience, allows us to offer exclusive processes. We systematically carry out random quality checks on all production batches, to verify compliance with the pre-established standards, in terms of performance and graphic quality. And, thanks to high tech management software, we trace every single component used from the beginning to the end of production, up to the packaging, in order to be able to identify any non-compliances, intervene promptly and resolve any problems.

Production

lines

for sachets and bags

- 4 colour Flexo printing unit

- format range

- - Width from 40 to 600 mm

- - Height from 50 to 920 mm

- - Height from 50 to 920 mm

- - Flaps from 15 to 200 mm, also adhesive

- - Flat/Square/Self-forming bottom

- - Open bottom (tubular)

- - Special machining according to projects

- 1 Flexo 6 colour printing line H.1500mm. with paper/film lamination with in-line rotary mechanical die cutter.

- 1 FlexoHD 10-colour paper and film printing line, H.1250mm. with in-line paper/film lamination.

- 1 film lamination/coating, film/solvent-free film and rotogravure line

- 1 line for coating and laminating paper/film with double laser for windowing/accurate pre-cutting.

- Min. 20mm. to max 1600 mm. cutting with electronic quality control. 76/152 mm. core hole with max. diameter 500mm.

- Min. 20mm. to max 1300 mm. cutting with electronic quality control. 76/152 mm. core hole with max. diameter 500 mm.

Customised

expert advice

In-depth knowledge of packaging methods combined with technical skills on packaging materials and machinery. This is the constantly evolving wealth on which we draw to offer personalised expert advice and the study of tailor-made offers for the customer. Our flexibility in dealing with specific requests allows us to create different and unique bags, sachets and packaging every time: from the material to the format, each choice responds to criteria of aesthetic functionality, to fully satisfy the customer’s expectations, including as concerns schedules. For each project, we resolutely pursue the goal of creating a bag able to stand out and enhance the content: it is the smallest detail that often creates a big difference.

Sources of

inspiration

What is the customer looking for?

That is the first question we ask ourselves in all our research and development processes. In fact, the customer and its needs are at the centre of our innovative activities: constant dialogue guides us to develop new products and new manufacturing methods, cutting-edge solutions to packaging problems, technical improvements on products or systems for packaging. The sources of inspiration for our innovations, moreover, include observing daily life, our own experience of how we use the bags we produce and the commitment to increasingly reduce the impact of packaging on the environment.

Need more information?

Or call us at

t. +39 049.5958487

Via San Giovanni, 13

35010 Carmignano di Brenta

Padova – IT

phone. +39 049.5958487

fax. +39 049.5958944

info@lineapacksrl.com